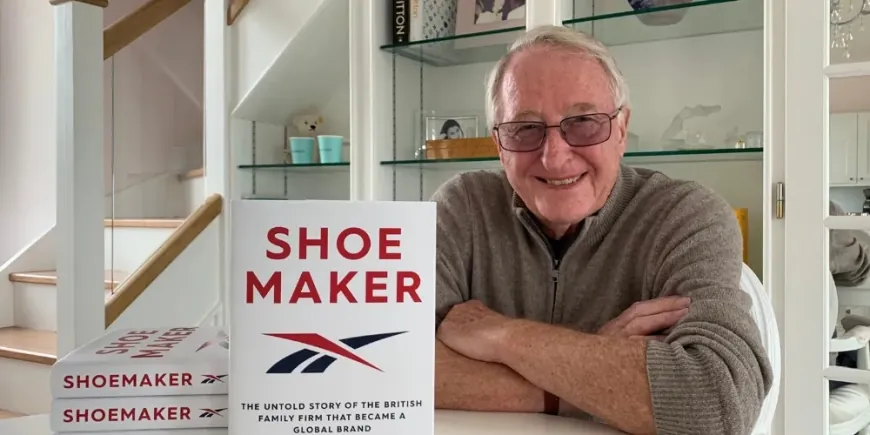

Reebok Founder: U.S. Sneaker Manufacturing Isn’t Possible After Trump’s Tariff Hike

Reebok founder Joe Foster says Trump’s tariffs won’t bring sneaker jobs back to the U.S., warning the skills and factories don’t exist here anymore.

Joe Foster, the 90-year-old founder of Reebok, says the idea of bringing sneaker production back to America in response to Trump’s new tariffs is “virtually impossible”—not because of corporate reluctance, but because the infrastructure simply doesn’t exist.

In a conversation about the footwear industry’s future, Foster made it clear: making sneakers isn’t like making smartphones or assembling cars. It requires thousands of skilled workers sitting at machines, day in and day out, stitching, molding, and assembling by hand. Those workers don’t exist in the U.S. today—and there’s no system in place to train or supply them at scale.

“You’ve got to go somewhere with people willing to sit on production lines,” Foster said. “That’s not something you can just ask for and get. In the U.K., we’ve tried. People won’t do it. The U.S. has the same problem.”

The Tariff Impact

The Trump administration’s latest tariff announcement puts sneaker companies in a bind. As of July 9, a 20% tariff on footwear imports from Vietnam is set to begin August 1. Vietnam has become one of the world’s largest sneaker producers, making shoes for Nike, Under Armour, Skechers, and Reebok.

To make matters worse for brands, the administration is also threatening a 30% tariff on products coming from Mexico, another key sourcing region for footwear and apparel. Meanwhile, the trade standoff with China continues unresolved—leaving the largest sneaker supply chain in limbo.

For sneaker companies, this isn’t just about shifting factories from one country to another. It’s about a global manufacturing system that’s been built over decades, with entire regions specializing in certain skills.

“The techniques and the people actually go with the machinery,” Foster explained. “It’s not just a case of moving machines to America or Mexico. The skills don’t come in a box with the hardware.”

Why Sneaker Manufacturing Can’t Just Come Home

Sneaker production is labor-intensive. Unlike electronics manufacturing, which can be heavily automated, shoemaking still relies on human hands for much of the process. Cutting leather, stitching panels, assembling soles—these tasks require skilled craftsmanship, even in large factories.

Asian factories, particularly in Vietnam and China, have developed vast supply chains around the footwear industry, including material sourcing, machinery maintenance, and worker training. The U.S. hasn’t had anything comparable since the mid-20th century.

That’s why companies like Nike and Reebok expanded manufacturing to Asia decades ago—not just for cheaper labor, but for capacity and know-how.

“We’ve spent 60 years building the shoe industry in Asia,” Foster said. “You can’t rebuild that in the U.S. overnight. You probably can’t rebuild it in 10 years.”

From Family Workshop to Global Brand

Joe Foster’s connection to the sneaker world isn’t just professional—it’s personal and generational. His grandfather, also named Joe Foster, designed one of the world’s first spiked running shoes in 1895 at the age of 15. That invention became the starting point for the family business, JW Foster & Sons.

Joe and his brother Jeff founded Reebok in 1958, transforming a small family operation into one of the most recognized athletic brands in the world. Foster retired in 1997, and Reebok was later sold to Adidas in 2005 for $3.8 billion.

Despite stepping back from the industry’s corporate side, Foster remains deeply involved in footwear innovation.

Foster Turns Attention to Fit, Not Factories

At 90, Joe Foster hasn’t fully stepped away from footwear. But his current work has little to do with tariffs or factories. He’s now collaborating with tech company Syntilay on a project aimed at making shoes that fit people more precisely.

The idea is simple: instead of making one-size-fits-all sneakers in massive factories, design shoes around the actual shape of someone’s feet. For Foster, the real issue isn’t about shifting production between countries—it’s about improving the product.

“It’s not just about where shoes are made,” he said. “It’s about whether they fit the person buying them.”

Also Read: Trump Announces 30% Tariffs on EU and Mexico After Trade Talks Fail